- Home

- POS advertising stands

- Cardboard ellipses

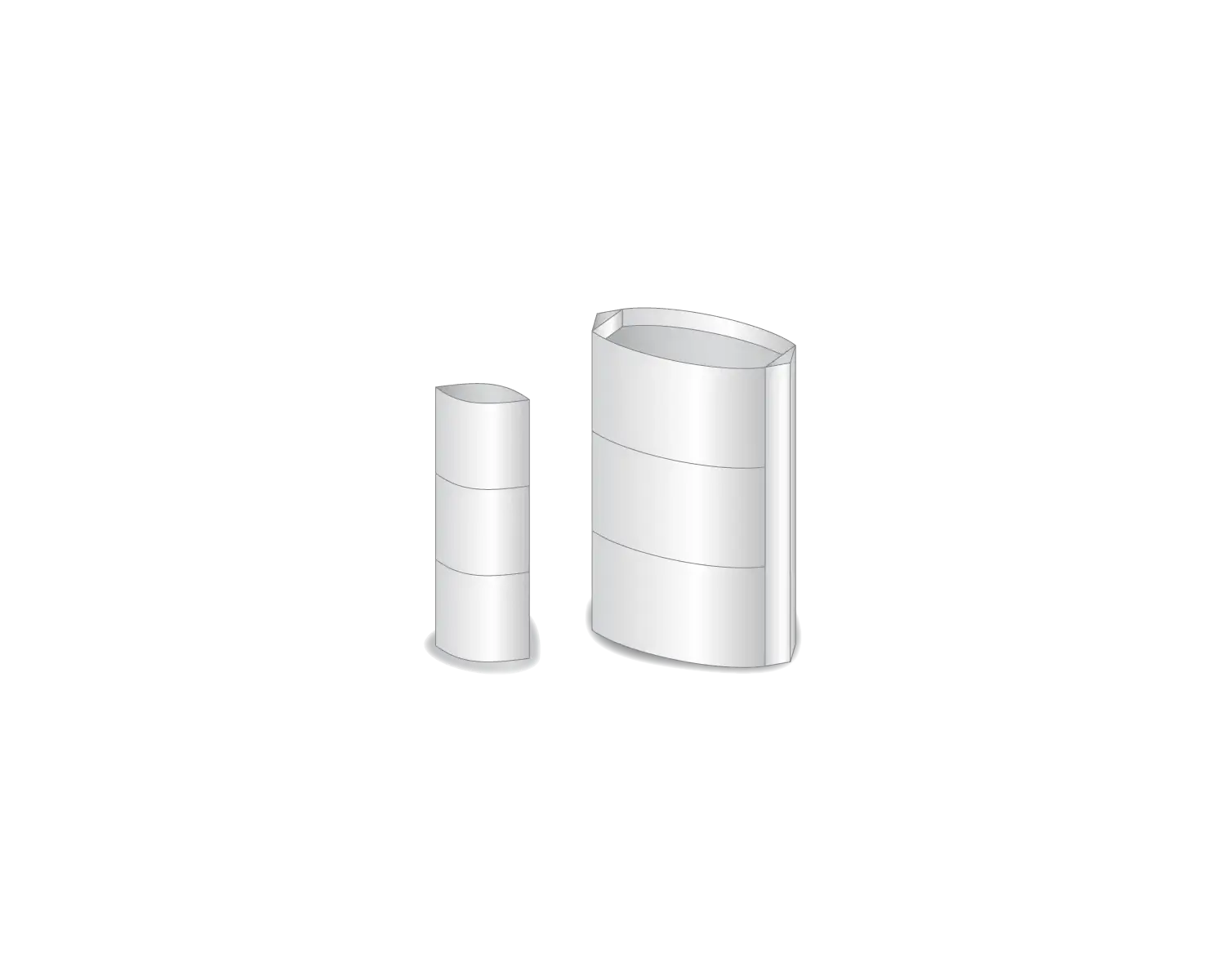

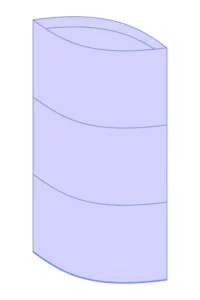

Cardboard ellipses (gate wraps)

Display POS

Cardboard ellipses are POS materials, used as advertising wrappers around entrance gates to a store/supermarket or as a free-standing advertising medium in cinemas (JUMBO version)

Types of advertising wrappers

gate wraps

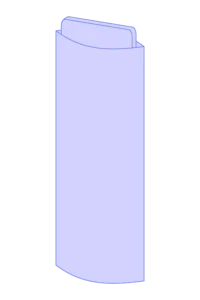

duple

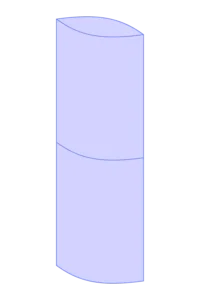

tripartite

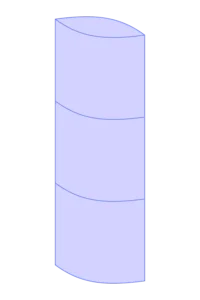

Cinema jambo ellipses without sides

Cinema jambo ellipses with sides

Product information

Where will cardboard ellipses be used?

Cardboard ellipses are advertising media supporting sales (POS), dedicated mainly to stores equipped with entrance / anti-theft gates, where they can be used in the form of wrappers.

Their reinforced structure (JUMBO version) is used as a free-standing advertising medium for cash registers and waiting rooms in cinemas.

Our offer includes standard ellipses, made of solid cardboard (the so-called advertising wrappers) and JUMBO ellipses (cinema ellipses), made of corrugated E and EB cardboard.

Innovative machinery and technology used in the LUXPOL Group allow us to fulfill all orders, including non-standard or large-size ones.

What are the ellipses made of?

Material

solid board / E corrugated board / EB corrugated board

Print area

up to 100%

Print colors

full colour

Lamination?

YES

Order processing time

from 3 working days