- Home

- POS advertising stands

- Cardboard gates

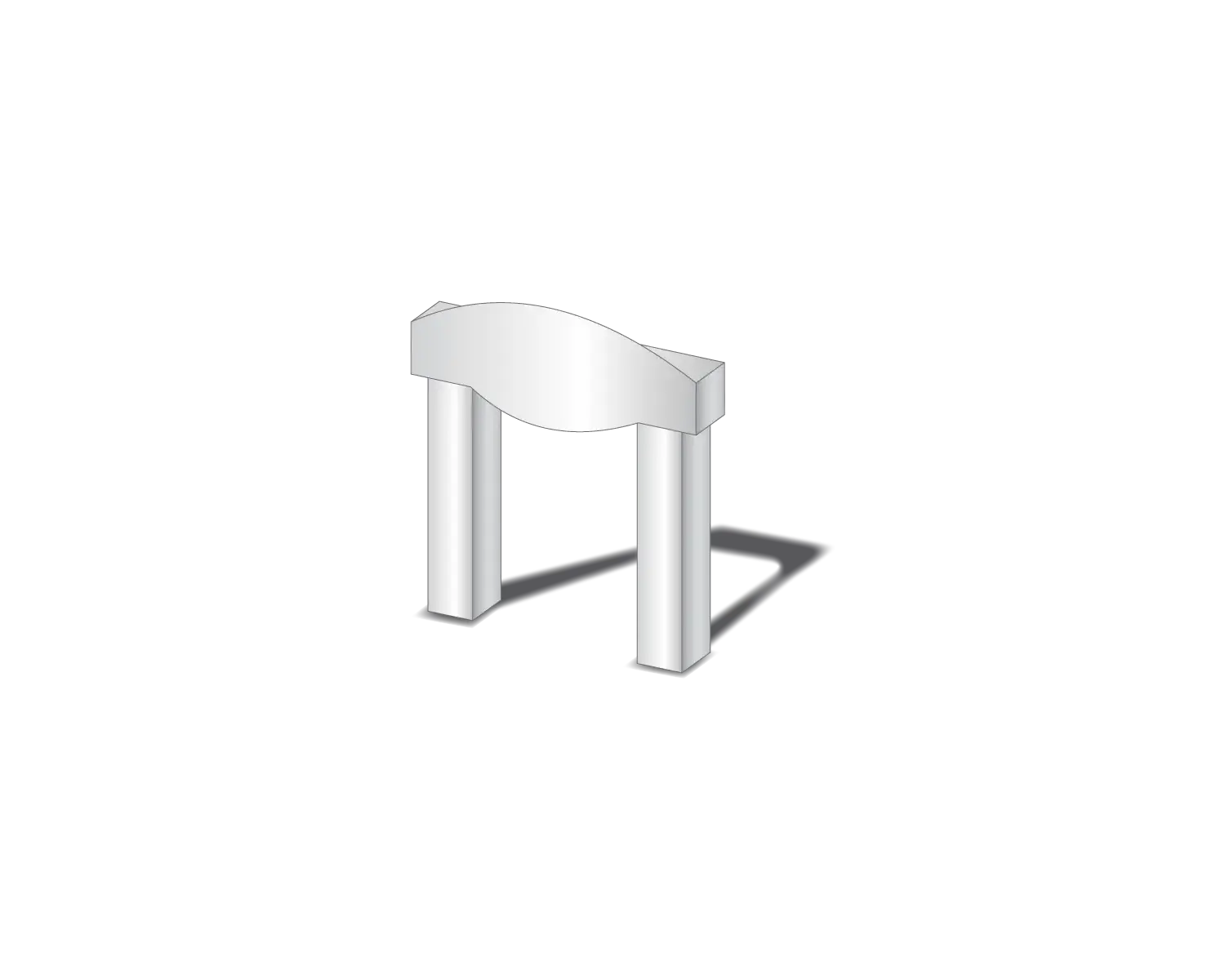

Cardboard gates

Display POS

Cardboard gates, made of ecological, lightweight EB corrugated cardboard, are a distinctive advertising medium designed for exhibition fairs or promotional hall events.

Product information

What can be the use of cardboard gates?

A cardboard gate is an ecological advertising medium and a unique way to distinguish a stand during exhibition fairs, market tastings of your product or as a free-standing element, e.g. during indoor sports competitions.

Our cardboard gates are made of light but very durable EB corrugated cardboard with a wave height of approx. 5 mm, which ensures their durability and stability of their construction.

In the LUXPOL Group, we provide comprehensive services for even the most demanding projects. Our offer covers all stages of preparation and production, from graphic design to shipping of finished materials.

We work on the most modern Kongsberg plotter on the market, which, among many available functions, provides e.g. milling, creasing and cutting from many different materials – from plastic, through wood, to cardboard. Thanks to the large working area of the table, i.e. 3250 x 2250 mm, we are able to carry out large-size orders.

What are the gates made of?

Material

corrugated board EB

Print area

up to 100%

Print colors

full colour

Lamination?

YES

Order processing time

from 3 working days