- Home

- POS advertising stands

- Cardboard walls

Cardboard walls

Display POS

Cardboard walls are light and stable advertising media with versatile promotional use. They can be a perfect background for photo sessions or act as an advertising billboard.

Types of walls

straight wall

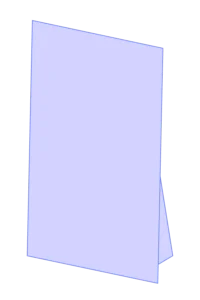

leg wall

panoramic wall

Product information

What function can cardboard walls perform?

Cardboard walls are very popular exhibition products, which, due to their lightness and mobility, are increasingly displacing classic pop-up exhibition walls.

They can act as free-standing, stable billboards or provide an attractive background for photo sessions, e.g. during film premieres, concerts or galas.

Our basic offer of cardboard walls includes two types: a wall with or without a leg, 200 to 250 cm high and 100 to 150 cm wide. Larger widths can be achieved by multiplying a single wall, thanks to which it is possible to develop even spectacular surfaces. The great advantage of the walls is their lightness, stability and ease of installation. The exhibition walls are made of durable EB corrugated board with a wave height of approx. 5 mm

The walls we offer are printed in the CMYK color palette up to 100% of the surface, ensuring perfect reproduction of colors and their saturation.

What materials are the walls made of?

Material

corrugated board EB

Print area

up to 100%

Print colors

full colour

Lamination?

YES

Order processing time

from 3 working days