- Home

- POS advertising stands

- Stands with hooks

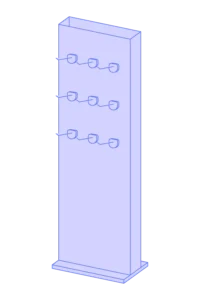

Stands with hooks

Display POS

Stands with hooks are a popular category of sales support carriers, equipped with stable and durable hooks that allow you to hang the displayed product.

Types of stands

wall with hooks

stand with hooks

Product information

What can you use hook stands for?

Stands with hooks are popular POS (point of sale) carriers, which are used during product campaigns in supermarkets and other retail outlets.

This is a special type of reinforced display, equipped with stable and durable hooks, thanks to which it is possible to present even better and more effective, for example, food products.

Our carriers with hooks are made in two types: a wall made of corrugated cardboard E (wave height approx. 5 mm) and a stand made of corrugated cardboard type EB (wave height approx. 5 mm), equipped with the so-called garden i.e. extended base with space inside. Regardless of the design or purpose, all products from our offer meet the highest safety and durability standards, thanks to which they can be successfully used even with regular exposure.

Thanks to innovative technology and many years of experience of our designers, we are happy to undertake even the most demanding projects.

How are hook stands made?

Material

E corrugated board / EB corrugated board

Print area

up to 100%

Print colors

full colour

Lamination?

YES

Order processing time

from 3 working days