- Home

- POS advertising stands

- Cardboard displays

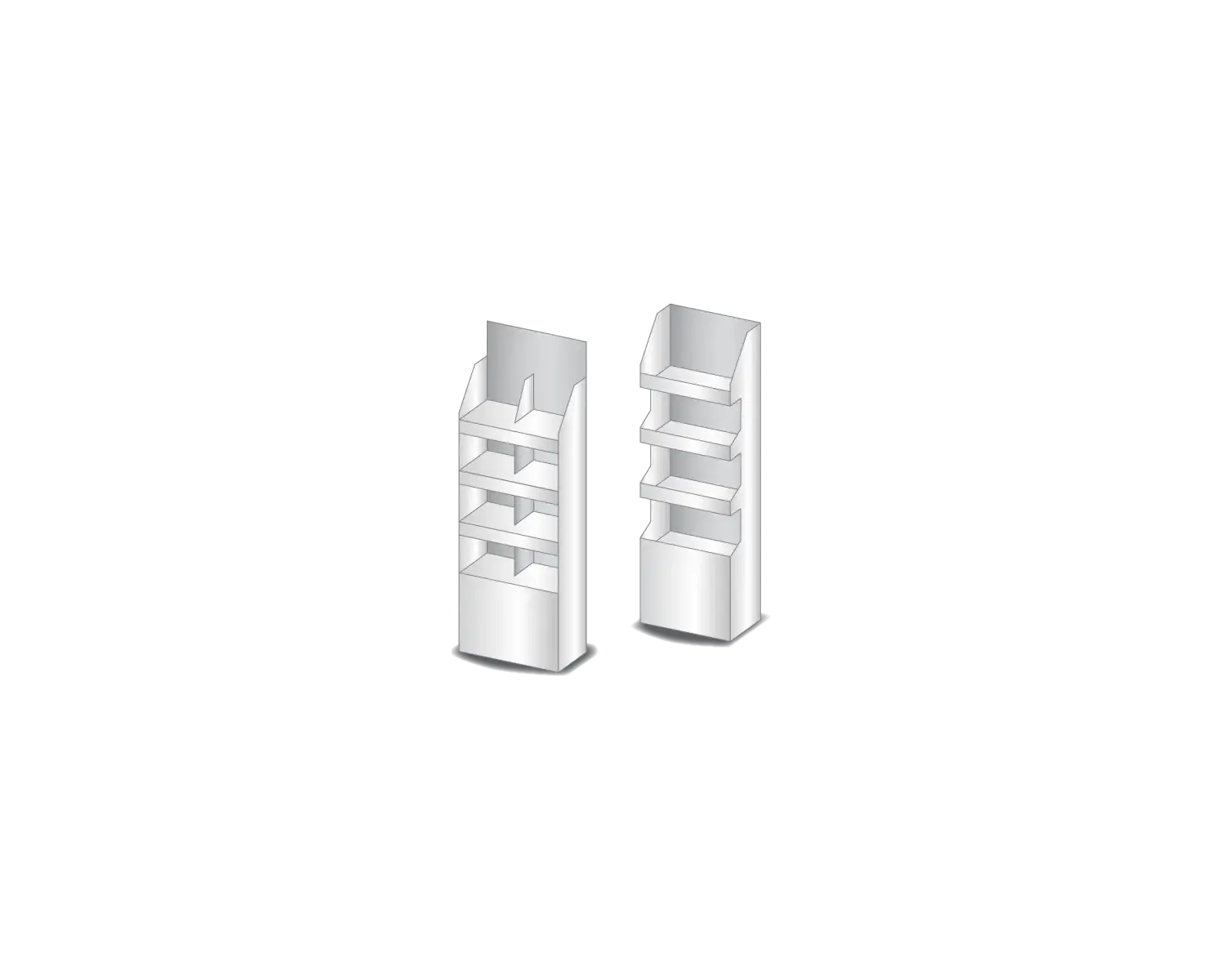

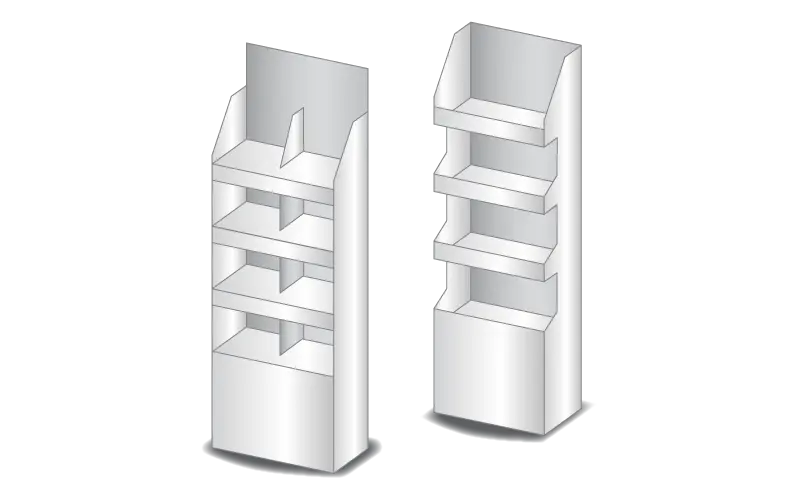

Cardboard display (shelf)

Display POS

Cardboard display is the most popular POS material (point of sale display), intended for the implementation of product promotional activities at checkouts and shelves with goods.

Types of cardboard displays

simple display

display with automatic shelves

display up to 10kg per shelf

budget simple

budget with compartments

budget load

Information about POS cardboard displays

What is a cardboard display used for?

A cardboard display is a type of POS stand equipped with shelves, used as a shop shelf and an attractive advertising medium during promotional activities at points of sale or tasting. Our offer is addressed in particular to producers from the FMCG (fast-moving consumer goods) industry, i.e. food or cleaning products.

Our standard offer includes as many as 6 carrier designs, personalized in terms of size and number of shelves. The displays are made of two types of materials, i.e. made of EB corrugated cardboard with a wave height of approx. 5 mm and corrugated cardboard E with a wave height of approx. 2 mm.

For the production of cardboard stands, we use Kongsberg technology, which, among many available functions, provides e.g. milling, creasing and cutting from many different materials – from plastic, through wood, to cardboard. With a working area of 3250 x 2250 mm, we are happy to undertake non-standard and large-size orders.

What are the stands made of?

Material

EB board/E corrugated board

Print area

up to 100%

Print colors

full colour

Lamination?

YES

Order processing time

from 3 working days